In 1876, a new phase begins in the history of the Nobel engineering works once Ludvig and his eldest son, Emanuel, had visited their brother Robert Nobel in Baku. After this, a lot of the manufacturing in the engineering works in St Petersburg is adapted to the great need for development of the Nobels’ oil industry in Baku.

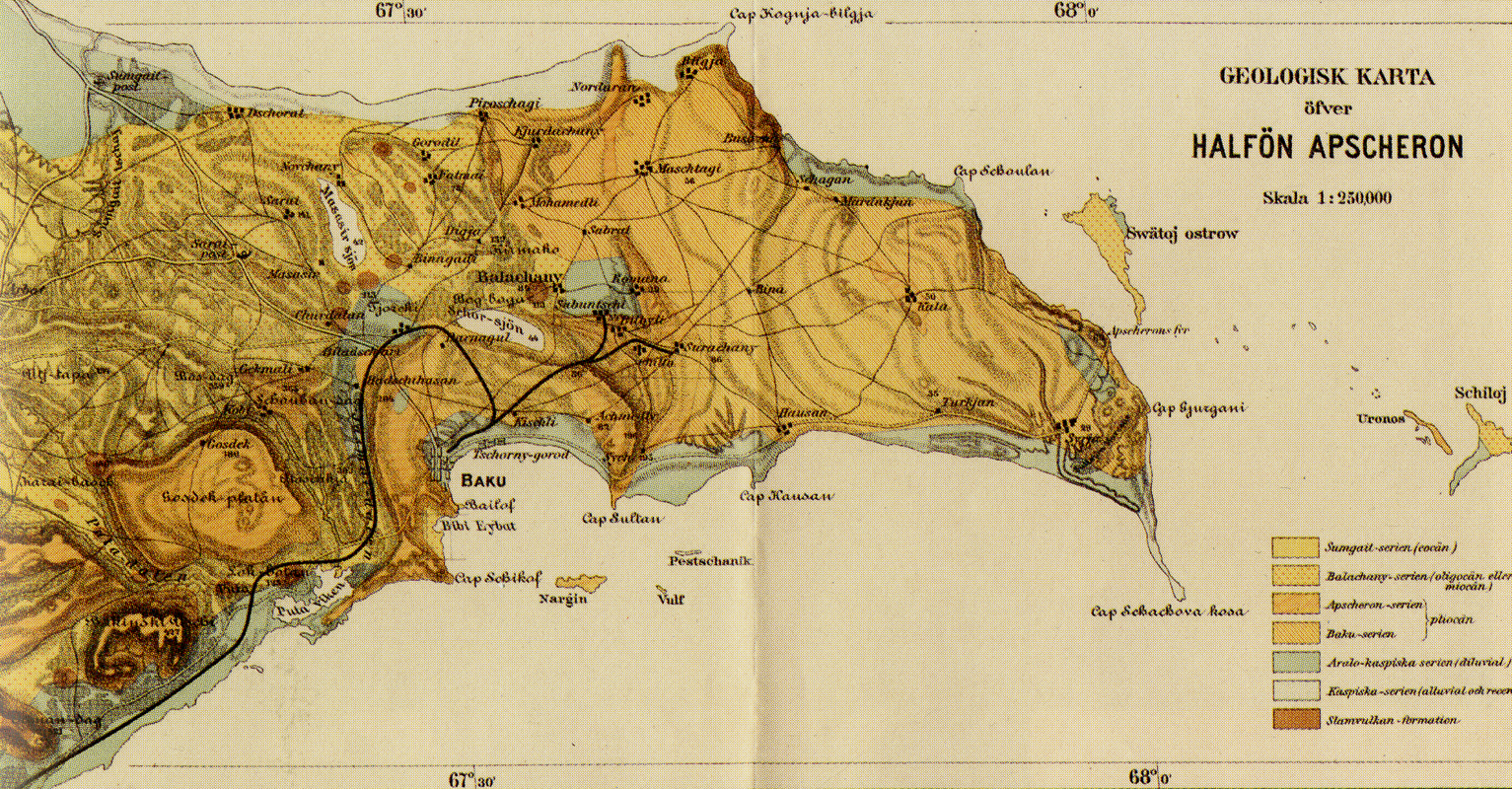

At this time, Robert Nobel had a factory with eight vertical distillation boilers, 100 puds each, and was producing good kerosene, i.e. paraffin. Robert and Ludvig devised a plan together for how the crude oil would be taken care of from the fields to the factories with pipes and steam pumps, how the transport of oil products by tankers and barges on the Caspian Sea and Volga would be organised and the necessity of replacing pits in the ground with iron cisterns for storing the oil. The Russian railway network also needed to be extended with tracks to the oil fields on the Absheron peninsula at Baku.

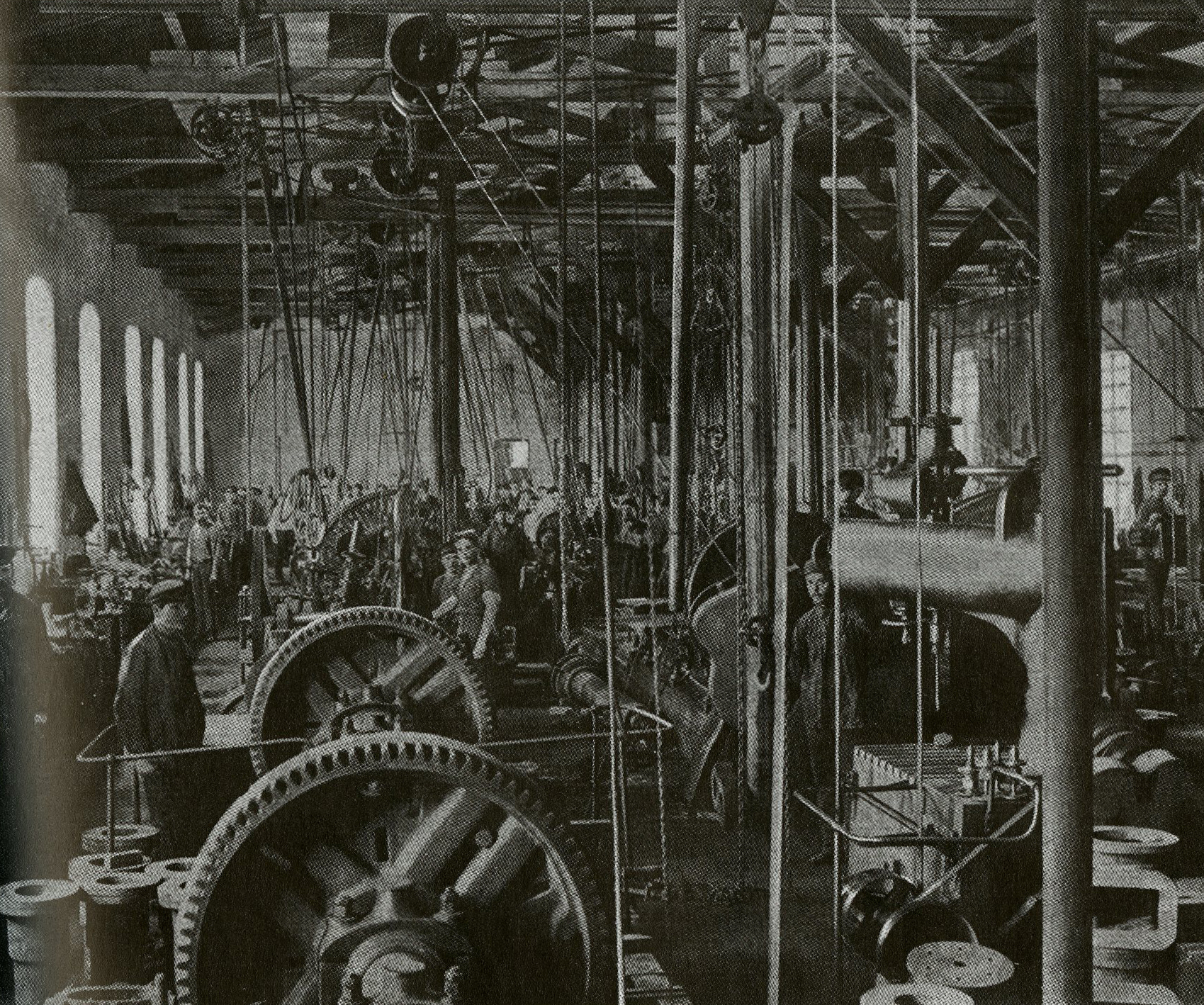

In the engineering works in St Petersburg, Ludvig produced steam engines, containers, bolts, accessories and crane machinery and carefully followed news about the new paraffin engine. Pump machinery was transported to Baku to transport the crude oil from the drilling fields to the distillation works. The factory produced steam pumps, pipes, flanges, ventilators, ball-bearing hinges, cisterns, more powerful steam engines and steam boilers for drilling stations and accessories.

A section within the factory began to make ventilators of the so-called Ludlow model in 12 different sizes, from 2 to 16 inches for oil and water pipes. Steam pumps were important. An American type, ”Blake” and later, ”Cameron” were suitable in Baku. These were manufactured on a fairly large scale until pumps of the Worthington type took over at the end of the 1880s. They could deliver 200 to 250 cubic metres an hour. Transmission and hand pumps for water and oil were also manufactured for use in the depots around Russia. Riedel pumps were later produced for use in connection with diesel engines.

The steam engines were now adapted to the needs of the oil industry. In the drilling towers, a powerful engine for drilling and extracting oil was necessary. A simple and powerful variant called the ”Baku engine” was made great use of over the initial period. The engine manufacturer, Ludvig Nobel, improved and adapted steam engines of the compound type up to 300 hp with great steam economy for, among other things, workshop operation and electrical lighting. Designs for firing with oil were important technical innovations. Steam boilers were built according to different systems, such as horizontal tubular boilers, vertical boilers with internal furnaces and waterpipe boilers. In 1883 – 1893, the Russian artillery administration ordered a number of traction-engine boilers on wheels with steam engines above the boiler.

Following the distillation of the crude oil a residue remained, called masut, which was previously regarded as worthless and mostly a problem. A change came with the new oil burner, ”the forsunk”, which Ludvig Nobel designed. Through this, the masut, with its high fuel value, came to be used in industry, steamships and railway operation. Its economic importance for the country’s industrialisation was invaluable. The masut was used to fire ovens through a system called Kolasniki Nobelja and this was found in furnaces and cookers in towns where the oil was easy to get hold of. The Swede, Wittenström, made metallurgical progress through the development of a process called ”mitis”, whereby waste from forging was smelted in crucibles. Some of the factory’s capable assistants worth a mention are B F Berg and M Kauffman.

After Ludvig Nobel’s death in 1888, his son, Carl Nobel, took over management of the Engineering Works. That same year, the factory was given the sole right to manufacture de Lavals’ cream separator in Russia. They were later purchased ready for use from Sweden by the independent company Alfa-Nobel, with Ludvig’s son, Emil Nobel, as manager.

When Carl Nobel died in 1894, his elder brother, Emanuel, took over management during a period of crisis in the Russian engineering industry. In 1898, Emanuel bought the patent for Rudolf Diesel’s engine and the diesel engine was later to drive out almost all other production.

(more info)

(more info)

(more info)